Bearing (mechanical)

From Wikipedia, the free encyclopedia

A bearing is a device to permit constrained relative motion between two parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can handle.

Contents |

Bearing friction

Low friction bearings are often important for efficiency, to reduce wear and to facilitate high speeds. Essentially, a bearing can reduce friction by virtue of its shape, by its material, or by introducing and containing a fluid between surfaces.

- By shape, gains advantage usually by using spheres or rollers.

- By material, exploits the nature of the bearing material used. (An example would be using plastics that have low surface friction.)

- By fluid, exploits the low viscosity of a layer of fluid, such as a lubricant or as a pressurized medium to keep the two solid parts from touching.

- By fields, exploits electromagnetic fields, such as magnetic fields, to keep solid parts from touching.

Combinations of these can even be employed with the same bearing. An example of this is where the cage is made of plastic, and it separates the rollers/balls, which reduce friction by their shape and finish.

Principles of operation

There are at least six common principles of operation:

- sliding bearings, usually called "bushes", "bushings", "journal bearings", "sleeve bearings", "rifle bearings", or "plain bearings"

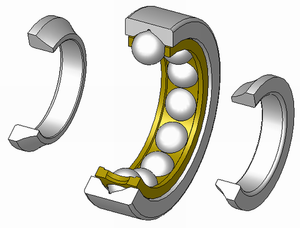

- rolling-element bearings such as ball bearings and roller bearings

- jewel bearings, in which the load is carried by rolling the axle slightly off-center

- fluid bearings, in which the load is carried by a gas or liquid

- magnetic bearings, in which the load is carried by a magnetic field

- flexure bearings, in which the motion is supported by a load element which bends.

Motions

Common motions permitted by bearings are:

- Axial rotation e.g. shaft rotation

- Linear motion e.g. drawer

- spherical rotation e.g. ball and socket joint

- hinge motion e.g. door

Loads

Bearings vary greatly over the size and directions of forces that they can support.

Forces can be predominately radial, axial (thrust bearings) or moments perpendicular to the main axis.

Speeds

Bearings vary typically involving some degree of relative movement between surfaces, and different types have limits as to the maximum relative surface speeds they can handle, and this can be specified as a speed in ft/s or m/s.

For rotational bearings generally performance is defined in terms of the product 'DN' where D is the diameter (often in mm) of the bearing and N is the rotation rate in revolutions per minute.

Generally in terms of relative speed of the moving parts there is considerable overlap between capabilities, but plain bearings can generally handle the lowest speeds while rolling element bearings are faster, followed by fluid bearings and finally magnetic bearings which have no known upper speed limit.

Life

Fluid and magnetic bearings can potentially give indefinite life.

Rolling element bearing life is statistical, but is determined by load, temperature, maintenance, vibration, lubrication and other factors.

For plain bearings some materials give much longer life than others. Some of the John Harrisonlignum vitae wood employed in their construction, whereas his metal clocks are seldom run due to potential wear. clocks still operate after hundreds of years because of the

Maintenance

Many bearings require periodic maintenance to prevent premature failure, although some such as fluid or magnetic bearings may require little maintenance.

Most bearings in high cycle operations need periodic lubrication and cleaning, and may require adjustment to minimise the effects of wear.

History and development

An early type of linear bearing was an arrangement of tree trunks laid down under sleds. This technology may date as far back as the construction of the Pyramids of Giza, though there is no definitive evidence. Modern linear bearings use a similar principle, sometimes with balls in place of rollers.

The first plain and rolling-element bearings were wood, but ceramic, sapphire or glass can be used, and steel, bronze, other metals, and plastic (e.g., nylon, polyoxymethylene, teflon, and UHMWPE) are all common today. Indeed, stone was even used in various forms. Think of the "jeweled pocket watch", which incorporated stones to reduce frictional loads, and allow a smoother running watch. Of course, with older, mechanical timepieces, the smoother the operating properties, then the higher the accuracy and value. Wooden bearings can still be seen today in old water mills where the water has implications for cooling and lubrication.

Rotary bearings are required for many applications, from heavy-duty use in vehicle axles and machine shafts, to precision clock parts. The simplest rotary bearing is the sleeve bearing, which is just a cylinder inserted between the wheel and its axle. This was followed by the roller bearing, in which the sleeve was replaced by a number of cylindrical rollers. Each roller behaves as an individual wheel. The first practical caged-roller bearing was invented in the mid-1740s by horologist John Harrison for his H3 marine timekeeper. This used the bearing for a very limited oscillating motion but Harrison also used a similar bearing in a truly rotary application in a contemporaneous regulator clock.

An early example of a wooden ball bearing (see rolling-element bearing), supporting a rotating table, was retrieved from the remains of the Roman Nemi ships in Lake Nemi, Italy. The wrecks were dated to 40 AD. Leonardo da Vinci is said to have described a type of ball bearing around the year 1500. One of the issues with ball bearings is that they can rub against each other, causing additional friction, but this can be prevented by enclosing the balls in a cage. The captured, or caged, ball bearing was originally described by Galileo in the 1600s. The mounting of bearings into a set was not accomplished for many years after that. The first patent for a ball race was by Philip Vaughan of Carmarthen in 1794.

Friedrich Fischer's idea from the year 1883 for milling and grinding balls of equal size and exact roundness by means of a suitable production machine formed the foundation for creation of an independent bearing industry.

The modern, self-aligning design of ball bearing is attributed to Sven Wingquist of the SKF1907. ball-bearing manufacturer in

Henry Timken, a 19th century visionary and innovator in carriage manufacturing, patented the tapered roller bearing, in 1898. The following year, he formed a company to produce his innovation. Through a century, the company grew to make bearings of all types, specialty steel and an array of related products and services.

The Timken Company (Sale $4,973.4M, 2006), The SKF company($6,195.1M, 2005), the Schaeffler Group (Private), the NSK company($5,344.5M, 2006), and the NTN Bearing company($3,697.8M, 2006) are now the largest bearing manufacturers in the world.

Types

There are many number of different types of bearings.

| Type | Description | Stiffness* | Speed | Life | Notes |

|---|---|---|---|---|---|

| plain bearing | rubbing surfaces, with lubricant | Good, provided wear is low, but some slack is normally present | low/moderate (often requires cooling) | moderate (depends on lubrication) | The simplest type of bearing, widely used, relatively high friction |

| Rolling element bearing | Ball or rollers are used to prevent or minimise rubbing | Good, but some slack is usually present | moderate-high (often requires cooling) | moderate (depends on lubrication, often requires maintenance) | Used for higher loads than plain bearings with lower friction |

| jewel bearing | off-center bearing rolls in seating | Low due to flexing | low | adequate (needs cleaning and lubrication requires maintenance) | Mainly used in low-load, high precision work such as clocks |

| fluid bearing | Fluid is forced between two faces and held in by edge seal | Very high | Very high- speeds usually limited by seals | Virtually infinite in some applications, may wear at startup/shutdown in some cases | Can fail quickly due to grit or dust or other contaminants. Maintenance free in continuous use. |

| magnetic bearings | Faces of bearing are kept separate by magnets (electromagnetseddy currents) or | low | Infinite | Infinite | Often needs considerable power. Maintenance free. |

| Flexure bearing | Material flexes to give and constrain movement | low | Very high | Very high or low depending on materials and strain in application | Limited range of movement |

2 comments:

A jewel bearing is a bearing in which a metal spindle turns in a jewel-lined pivot hole. The hole is typically shaped like a torus and is slightly larger than the shaft diameter. In operation, the shaft tilts slightly so as to contact the jewel pivot hole at two opposite points.[citation needed] The shaft rolls inside the bearing rather than sliding.[citation needed] As the shaft rolls, the center precesses. Jewel bearings were invented in 1704 for use in watches by Nicolas Fatio de Duillier, Peter Debaufre and Jacob Debaufre who received an English patent for the idea. Originally natural jewels were used, such as sapphire, ruby, and garnet. In 1902 a process to make synthetic sapphire and ruby (crystalline aluminum oxide also known as corundum) was invented by Auguste Verneuil, making jewelled bearings much less expensive. Today most jewelled bearings are synthetic sapphire.

The advantages of jewel bearings include high accuracy, very small size and weight, low and predictable friction including good temperature stability, ability to operate without lubrication and in corrosive environments. They are known for their low static friction and highly consistent dynamic friction. The static coefficient of friction of brass-on-steel is 0.35, while that of sapphire-on-steel is 0.1-0.15.Sapphire surfaces are very hard and durable, with Mohs hardness of 9 and Knoop hardness of 2000, and can maintain smoothness over decades of use, thus reducing friction variability.[1] Disadvantages include brittleness and fragility, limited availability/applicability in medium and large bearing sizes and capacities, and friction variations if the load is not axial.

The largest use for jewel bearings is in mechanical watches, where their low and predictable friction improves watch accuracy. A typical mark of watch quality was a note such as "17 jewels". More jewel bearings often meant better precision. Some makers added non-functional or unnecessary jewels to give the impression of accuracy. Some watches had as many as 100 jewels, most of them of no use. A typical "fully jeweled" time-only watch has two cap jewels, two pivot jewels, an impulse jewel for the balance wheel, two pivot jewels, two pallet jewels for the pallet fork, and two pivot jewels each for the escape, fourth, third and center wheels. Modern electronic watches achieve accuracy entirely separate from the friction of the mechanism, but early quartz watches used jewels to increase battery life, and high-grade quartz watches use jewels to reduce friction and wear.

Today, jewel bearings are also used widely in sensitive measuring equipment. They are typically used for very small applications such as high-precision instruments; galvanometers, compasses, gimbals, and turbine flow meters. Bearing bores are typically less than 1 mm and typically support loads of under 1 gram, although they are made as large as 10 mm and support loads up to about 500 g.

Historically, jewel pivots were made by grinding using diamond abrasive. Modern jewel pivots are often made using high-powered lasers, chemical etching, and ultrasonic milling.

i have a useful post for how to select bearing flow chart.

Post a Comment